3D Printing

My friends are getting printers! These are my tips. Not particularly organized, just my advice for the process.

Create and Edit Files

You make teh DANG file!!!

- Solidworks

- Autodesk Fusion 360

- Blender

export to STL, z up

Oversize holes by like 3%.

Slicing

Ultimaker Cura is good, or at least popular. Has had a setting to do everything I’ve ever wanted. For some reason is really slow with certain operations.

Octoprint

Link to their site running on a raspberry pi. The pi is connected to my wifi.

Printer Firmware

If you’re running a regular reprap based board, marlin is good and has a lot of info. If you already have the Arduino software installed and working, its painless.

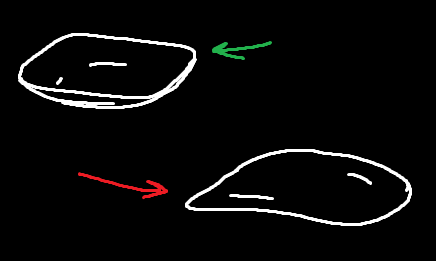

Bed Leveling

If this is the first level after a move or reassembly, lower the bed through like 3/4 of the travel of your bed spring bolts. This will stop the print head ramming into the bed when it tries to home.

Turn on your bed heater to like 50C. Those things expand. Clear off any gunk on the end of the hotend.

If you don’t have bed height sensors, you need to actually do stuff. Grab a piece of standard printer paper. You can use super lightweight stuff, or higher weight, and itll be different. But itll all stick.

Then using Marlin’s bed leveling program, go to each of the corners.

On the first pass, try to get close but don’t obsess over the perfect height.

On the second pass, start trying to lower it so you can still slide the paper around semi-easily, but you can ‘feel’ the resistance of the hotend touching it. Don’t reuse the same path on the paper, it can get compressed in the Z direction and the height will be too small.

On the third pass, you can expect to actually get it right.

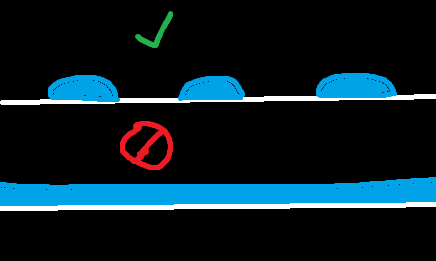

Likely, your bed will have some warp. Its always better to warp shaped like a bowl instead of a mountain, because the edges will stick better than the center. Sure, Marlin attempts to correct for it, but its not perfect.

Bed Adhesion

Use skirts on your prints. If you have to use a raft, you don’t know the right settings for your printer. If you have to use a brim to keep your print from peeling up, you arent heating your bed enough, or not using the right adhesion method.

On a glass bed, Aquanet Hair Spray is the best there is. The only thing better than a glass bed is that fancy Prusa textured flexible bed.

- Clean your bed with rubbing alcohol or something. Get it shiny.

- Heat your bed to around 50C.

- Use the piece of paper you level your bed with, and BLOCK THE HOTEND ASSEMBLY. You do not want this stuff on fans, heaters, insulation. It is flammable. FAMOUSLY! It is the most flammable compressed gas i have in my house.

-

In short bursts, spray a small amount of hairspray on the bed. Use short bursts because it changes the particle size. In that burst, make sure to press down the nozzle about 70% down. You want the bed to be coated in many small dots of hairspray. If you spray too much, it will turn into a film that doesn’t work as well.

This is good to start printing. Some of the spray will come off with the prints, so the center of the bed will loose its coating faster than the rest. You can reapply the coating to affected areas without cleaning the whole bed.

After a while, dust, plastic, and other gunk will make the bed just too dirty. Aquanet is water-soluble, so you can just get a wet paper towel and wipe it off. Re-apply the coat and you’re good.

Starting the Print

As the print starts drawing the skirt, pay attention to how it adheres. ADJUST THE BED AS IT PRINTS THE SKIRT. This is how you can adjust how low your bed rides, where in the ‘bowl’ your head will be printing’s edges are.

After the first 2 minutes of the print, you will be pretty confident in how the print will turn out. Just check on things every few minutes.

Finishing the print

Let the bed cool down below 35, and the hairspray will release its hold. Knock the object off the bed.